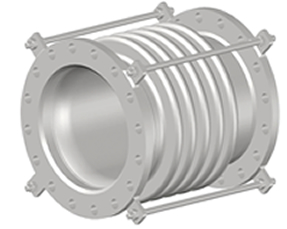

In building construction, an expansion joint is a mid-structure separation designed to relieve stress on building materials caused by building movement induced by:

- – Thermal expansion and contraction caused by temperature changes

- – Sway caused by wind

- – Seismic events

- – Static load deflection

- – Live load deflection

Because the joint bisects the entire structure, it marks a gap through all building assemblies–walls; decks; plazas or split-slab concourses; foundation floors and walls; roofs, planters, and green roofs; fire-rated demising walls and floors; interior floors; etc. This gap must be filled to restore the waterproofing, fire proofing, sound proofing, air barrier, roof membrane, trafficable surface and other functions of the building elements it bisects.